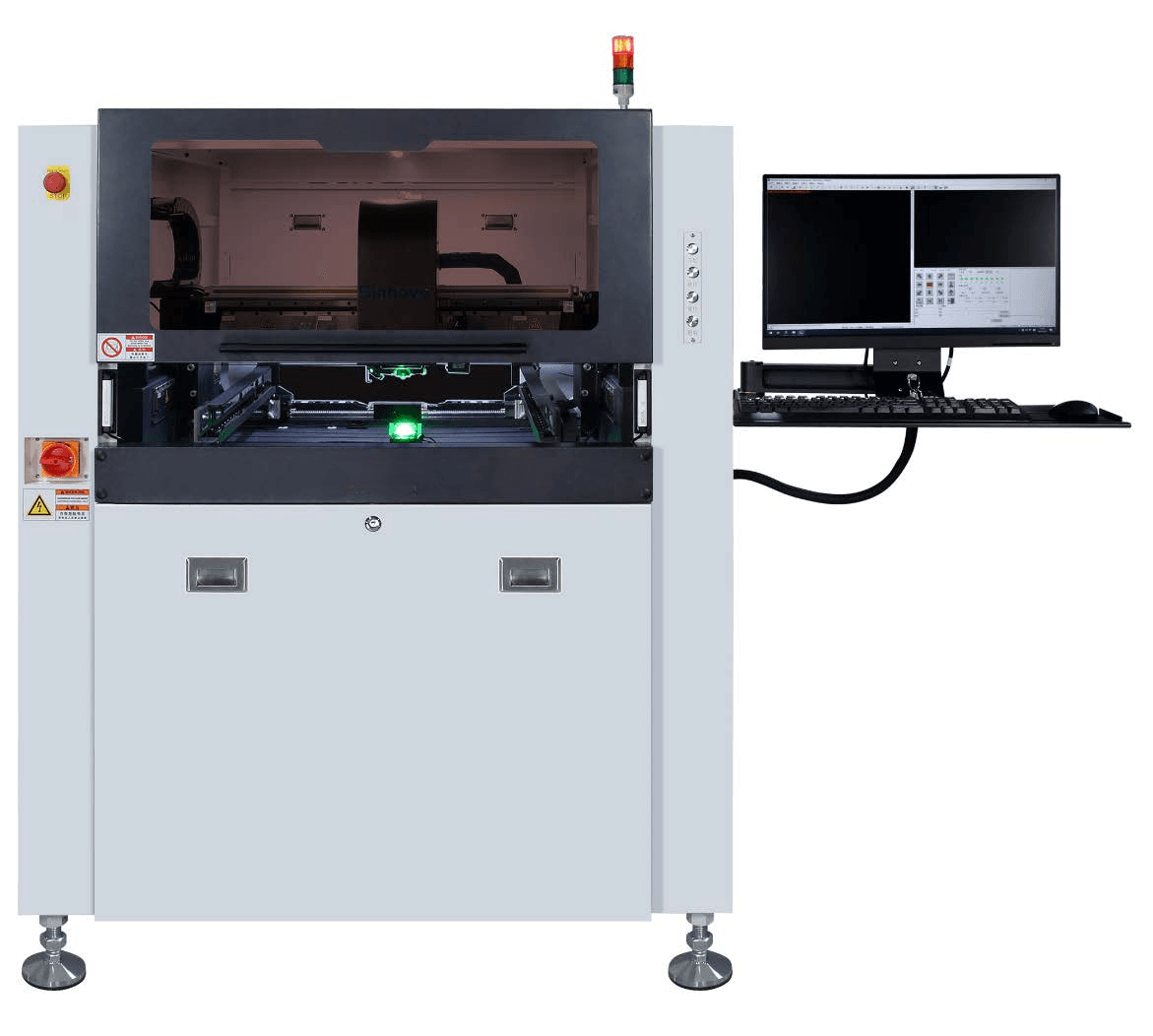

Die automatische Schabloneninspektionsmaschine VG830 von V2 ist für die hochpräzise Inspektion von gedruckten

Schablonen.

The Die automatische Schabloneninspektionsmaschine VG830 ist ein fortschrittliches optisches Inspektionsgerät, das zur Verbesserung der Präzision von SMT-Prozessen (Surface Mount Technology) entwickelt wurde. Es beginnt mit dem Einsatz automatischer Bildverarbeitungstechnologie, um umfassende Daten über die Größe und Positionierung von Schablonenöffnungen zu sammeln. Diese Informationen werden dann sorgfältig mit vordefinierten Parametern innerhalb des Systems verglichen, wodurch strenge Qualitätskontrollmaßnahmen für die Schablonen ermöglicht werden.

Key Vorteile gegenüber der manuellen Inspektion:

Precision & Konsistenz: Im Gegensatz zu herkömmlichen manuellen Methoden, die mit Konsistenz und Genauigkeit zu kämpfen haben, liefern unsere Inspektionsmaschinen präzise Messungen und objektive Vergleiche und eliminieren menschliche Fehler.

Data Integration: Bei manuellen Inspektionen fehlt die Möglichkeit, Daten effizient aufzuzeichnen und zu analysieren. Unser System integriert die Inspektionsergebnisse nahtlos in Datenbanken und ermöglicht so eine eingehende Analyse der Auswirkungen von Bohrtechniken auf die Qualität.

Ease Benutzerfreundlichkeit: Die Bedienung unserer Inspektionsmaschinen ist benutzerfreundlich und vollständig automatisiert, was schnelle Inspektionszyklen gewährleistet und subjektive Beurteilungen aus dem Prozess entfernt. Dies führt zu unvoreingenommenen, zuverlässigen Daten, die für die Qualitätssicherung entscheidend sind.

Specialized Funktionalität: Unsere Geräte sind auf die Überprüfung der Abmessungen und der Platzierungsgenauigkeit neuer Schablonenöffnungen sowie auf die Überwachung des Zustands und der Abnutzung bestehender Schablonen spezialisiert. Die frühzeitige Erkennung von Verschlechterungen oder minderwertigen Schablonen verhindert, dass PCB-Chargen aufgrund schlechter Schablonenqualität beeinträchtigt werden.

Adaptive Anpassen und Prüfen: Die Prüfmaschinen stellen sich automatisch auf verschiedene Schablonengrößen ein, führen Spannungstests durch und dokumentieren die Ergebnisse, so dass die Genauigkeit jeder Schablone im Laufe der Zeit kontinuierlich verfolgt werden kann.

Comprehensive Abdeckung: Egal, ob es sich um Standard- oder Leiterplattenschablonen handelt, unsere Inspektionsmaschinen stellen sicher, dass die höchsten Fertigungsstandards eingehalten werden, indem sie sowohl die Integrität neuer Schablonen als auch die Präzision der Produktionsmethoden überprüfen.

Enhanced Verifizierung: Durch den Abgleich der erfassten Daten mit PCB GERBER- und Schablonen GERBER/CAD-Dateien führen unsere Inspektionsmaschinen mehrstufige Vergleiche durch. Diese Offline-Prüfung bestätigt die Authentizität der Dateien vor dem Einsatz in der Produktion und stellt eine zusätzliche Ebene der Qualitätskontrolle dar.

Proactive Qualitätsmanagement: Die Integration unserer Schabloneninspektionsmaschinen in automatisierte Managementsysteme ermöglicht die frühzeitige Erkennung und Behebung von nicht konformen Schablonen und sichert so die gesamte Produktionseffizienz und Produktqualität.

Die automatische Schabloneninspektionsmaschine VG830 spielt eine entscheidende Rolle bei der Verfeinerung der Schablonenbohrmethoden und bei der Bewältigung komplizierter Druckherausforderungen, was direkt zu einer höheren Ausbeute beim ersten Durchlauf der Lotpasteninspektion (SPI) beiträgt. Durch die sorgfältige Aufzeichnung von Inspektionsdaten.

Die Systeme von The erstellen umfassende Berichte, die jeden Aspekt des Inspektionsprozesses abdecken. Diese detaillierten Einblicke erleichtern gründliche technische Analysen und liefern unschätzbare Unterstützung für kontinuierliche Verbesserungsinitiativen, um optimale Leistung und Qualität in der gesamten Produktionslinie zu gewährleisten.