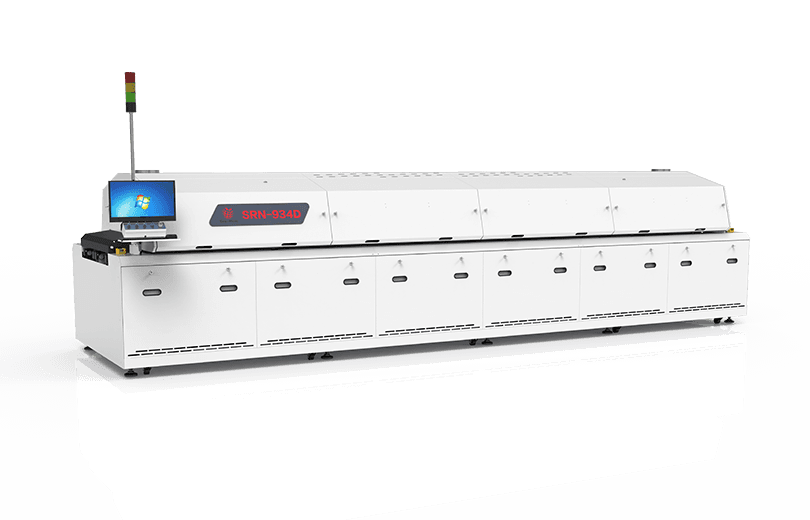

| Standardmerkmale des Fördersystems |

| Schienenstruktur | Subsection Integrated Type |

| Max.WidthOf PCB | 400mm(Option:460mm ) | Motorized; Twin lanes width adjustable 50~250mm or Single lane 50~490mm | 610mm (Option: 686mm ) | 400mm(Option:460mm ) | Motorized; Twin lanes width adjustable 50~250mm or Single lane 50~490mm | 610mm (Option:686mm ) |

| Range Of Rail Width/Adjustment | 50–400mm/ Motorized | 50–610mm/ Electric Motorized | 50–400mm/ Motorized | 50–610mm/ Electric Motorized |

| Komponenten Freigabe | PCB board 30/bottom 25mm, Top 30/Bottom 25mm |

| Richtung des Förderers | Von links nach rechts L→R (Option: Von rechts nach links R→L) |

| Transportschiene feste Methode Feste Schiene Seite | Front Rail Fixed (Option:Rear Rail Fixed) | Front and Rear End Rails Fixed, 2 Central Rail adjustable. | Front Rail Fixed (Option:Rear Rail Fixed) | Front Rail Fixed (Option:Rear Rail Fixed) | Front and Rear End Rails Fixed, 2 Central Rail adjustable. | Front Rail Fixed (Option:Rear Rail Fixed) |

| PCB-Transportmethoden PCB-Transportmittel | N2-Reflow = Chain only and Mesh optional |

| Center Support (Option) | Preventing PCB warp such too wide and heavy component load |

| Höhe des Förderbandes | 900±20mm |

| Conveyor Speed Range | 300~2000mm/min |

| Schmierung Auto-Afflux | Standard-Konfiguration |

| Thermal Management System and Analysis System |

| Electrical driven Top Hood Opening | Standard-Konfiguration |

| On line Editing | Standard-Konfiguration |

| Prozessgase N2 |

| Flux Management System | Flux Reclaimed and Filtration standard for N2 Oven, easy clean-up. |

| N2-Eindämmung am Eingang und Ausgang | Standard-Konfiguration |

| Flussmittel-Rückgewinnungssystem | Standard-Konfiguration |

| Stickstoff-Durchflussmesser | Standard-Konfiguration |

| Sauerstoff-Analysator | Standard-Konfiguration |

| Stickstoffverbrauch [Standard] | 300~1000PPM at15-20m³/hr (nitrogen purity 99.999%, 0.4~0.7MPa) |

| Nitrogen consumption (Dilated hearth) | 500~1000PPM at 20~25m³/hr (nitrogen purity 99.999%, 0.4~0.7MPa) |

| Water Chiller | 3HP External Stand-alone Type, Powerful Cooling suit to Lead-Free Process Required | 5HP External Stand-alone Type, Powerful Cooling suitable to Lead-Free Process Required |

| External Circuiating Cooling Water Requirements | Inlet water temperature: ≤25℃; outlet water temperature: ice water coming out of the furnace increases by 3-10℃; PH value: 7-9; suspended matter: no metal particles, no impurities; flow rate: 3M3/h; inlet water pressure: 1-2kgf; return water pressure difference 0.5kgf; inlet and outlet water pipe diameter: Φ25mm; |

| Note: The power indicated in the above BOM does not include the chiller power. |